Concrete is the most popular building material used around the world. It is known for its strength, reliability, and durability. Today, concrete is available in different types based on the admixtures and ingredients used. The difference in these mixtures is there to ensure the needs and preferences of anyone using it for building structures of various types. Below are the popular questions people ask about ready-mix concrete and you should know their answers too before ordering ready mix concrete delivery.

What Is Ready-Mix Concrete?

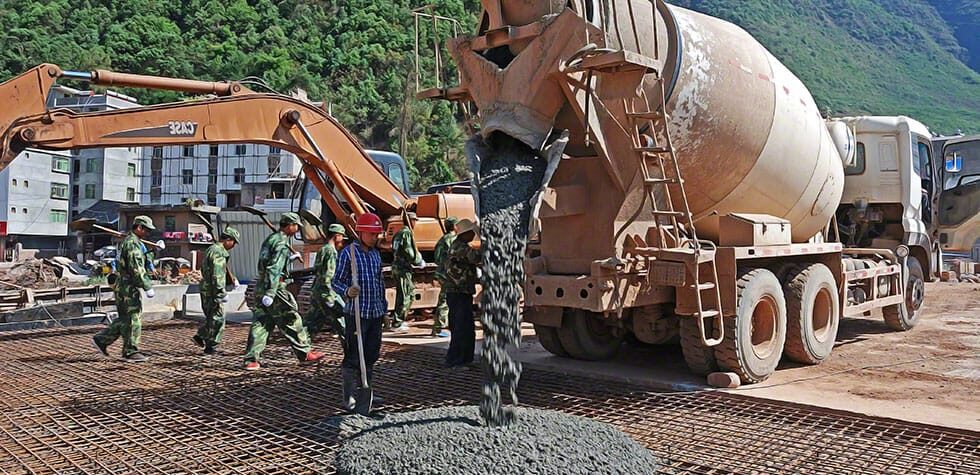

Ready-mix concrete is a type of concrete that is prepared at the manufacturing facility and is delivered to the construction site only to be spread and cured. This type of concrete is manufactured under controlled circumstances, depending on the nature and type of the project.

As mentioned earlier, ready-mix concrete comes in different types depending on the needs and preferences of the contractors or homeowners. For instance, ready-mix concrete used for repairing structures is going to be different than the one used for building structures from the ground up. The types will vary in building structures as well because ready-mix concrete required for building a pool may be different than the one required for building a house.

Ready-mix concrete uses water and other types of aggregates to ensure strength, performance, and durability. Concrete used for commercial projects contains all types of admixtures and other ingredients to ensure they are able to withstand the test of time.

During the manufacturing process of ready-mix concrete, experts keep a close eye on the mixing process to ensure a perfect result. Even a minor mistake could ruin the entire mixture and force the experts to start all over again.

This is why, to ensure optimum performance, experts choose to manufacture ready-mix concrete in a controlled environment under the supervision of an expert.

What Are The Advantages Of Ready-Mix Concrete?

Now that you are aware of the concept behind ready-mix concrete, it is time to discuss the advantages of ready-mix concrete.

The biggest advantage of ready-mix concrete is that it is prepared in a manufacturing facility and delivered in special trucks to keep it fresh until reaching the destination. This saves a lot of time and space while the team at the construction site does not have to worry about cleaning and removing the leftover concrete.

Furthermore, since concrete is manufactured under controlled environments, it is a lot easier for the experts to maintain consistency and deliver a product that matches the requirements of the project. In addition to that, ready-mix concrete is supplied by the manufacturing facility with the help of expert drivers who ensure the concrete does not dry up during the delivery process.

And, another noteworthy advantage of ready-mix concrete is that it is relatively more environmentally friendly than mixing and manufacturing concrete onsite. Ready-mix concrete reduces noise and dust pollution, making the construction site a lot safer and sustainable.

However, the team at the construction site needs to be fully trained to be able to handle unexpected situations. Concrete application requires skills and expertise. You need to deploy the best skills to make sure concrete withstands the test of time.

What Are The Disadvantages Of Ready-Mix Concrete?

While there are some notable advantages of ready-mix concrete, there are some disadvantages that need to be considered as well. Here are a few.

Since ready-mix concrete is manufactured at the facility, it needs to be delivered as quickly as possible to ensure it remains fresh. This means the manufacturer might have to employ multiple trucks and acquire permits to be allowed to use busy roads.

The transportation process can also take time, especially if the trucks are supposed to go through narrow streets and roads. As a result, the local authorities might have to shut down the road for regular traffic, which will cause inconvenience to regular users.

Additionally, if you were to choose an inexperienced supplier or manufacturer, they might not use the right type and quantity of ingredients to ensure a proper mix. As tempting as it might seem, opting for a cheap supplier is not going to solve your problems but instead add to them.

Finally, ready-mix concrete can be expensive depending on the region, delivery charges, and other factors. When choosing a supplier or manufacturer for concrete, you should choose the nearest source to the construction site to reduce the delivery time and costs.

How To Choose The Right Ready-Mix Concrete Manufacturer?

For picking the right concrete supplier Potomac, you will have to consider some important factors. To begin with, don’t be tempted by offers that are too cheap. Instead, you should only consider those options that are approved by the state.

The reason is that some regions have strict regulations pertaining to construction and industry laws. You will always find someone who is trying to bypass them to earn more profit. If you think opting for someone cheaper than the others is a smart move, you are simply calling for trouble.

Instead, you should either personally visit or interview the options over a phone call. If possible, you should personally visit and check out the manufacturing facility to ensure the practices and standards are top-notch. Once you have gathered multiple options, cross-compare them and pick the one that offers the best package.

How To Utilize Ready-Mix Concrete The Best Way?

Once concrete is ready to be delivered and used, you should be aware of the techniques and practices that will ensure concrete is used the right way.

As soon as you place an order for concrete, you should assess the construction site and remove any obstacles or hurdles. This helps reduce the time for the delivery trucks to make their way safely into the construction site without having to worry about the concrete drying up.

Although the trucks are specifically designed to keep the concrete fresh, that does not mean they account for longer delivery timelines. The contractors should be in contact with the supplier to minimize downtime and maximize efficiency.

If the supplier does not have any information about the job site and blindly trusts the contractor, they are most probably going to end up wasting the concrete mixture, as the contractor won’t be ready to accept the delivery either.

In addition to that, the contractors should also plan the transportation routes with the manufacturer. This ensures both teams are on the same boat and there is less chance of things going wrong.

Conclusion

When choosing ready-mix concrete and a supplier, the key is to find a ready mix concrete supplier Silver Spring who is approved and licensed by the state to ensure industrial practices are followed. On the other hand, it is your responsibility to ensure there are no delivery hurdles and your team is ready to handle concrete as soon as it shows up at the site.